Project Events

France, Paris, 8 May 2022

From 28 April to 9 May 2022 in Paris, France, the 121st Concours Lépine took place – a competition for the most original and useful inventions. This time, the Newex project team submitted an invention entitled “Active segment of a plasticizing assembly of the single-screw extruder”, whose authors were Prof. Janusz Sikora and M.Sc. Łukasz Majewski (Polish Patent No. 235891). After interviewing the authors, the international jury awarded the solution developed under the Newex project with a silver medal. It is already the 4th awarded solution created during this project. We wish you further success.

Portugal, Funchal, 2-4 May 2022

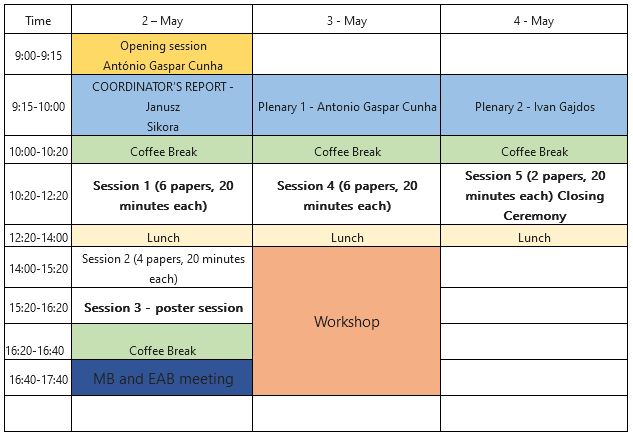

In order to summarise all the activities, results and dissemination of the project’s results, a conference was organised from 2 to 4 May 2022 to summarise the Newex project, called International Conference on Processing of Composites and Nanocomposites Materials, which also included training T5.2.4. The conference was attended by the majority of NEWEX project members (29 members) and members of the EAB team. The conference programme is presented below:

NEWEX Conference

Program

Poland, Lublin, 30 April 2022

On April 30, 2022 the last secondments at the host institution – Lublin University of Technology (Poland) were completed, which were attended by Secondees from Dirmeta company (Lithuania) and SEZ Krompachy company (Slovakia). Their main task was to compare the performance of the extruder, the extrusion process and the properties of the extrudate obtained in the conventional process with the performance of the extruder, the extrusion process and the respective properties of the extrudate obtained as a result of the extrusion process carried out using a new generation extruder, designed and built during the NEWEX project. This final stage of work has been completed, the report compiled and the deliverable submitted.

During the secondments to the LUT, on 22 April 2022, a T5.4c workshop on inter-sector and international cooperation was held according to the project plan, as part of the implementation of T4.3.

Poland, Lublin, 2 March 2022

The last secondments have started. Teams from SEZ and LUT came to LUT again. Times are difficult because we work in a sanitary regime. We hope that task 4.3 will be completed by the end of April 2022, we have to carry out comparative tests of extruders, extrusion processes and the obtained extrudate from March 1 to April 30.

Slovakia, Kosice, 18 February 2022

Next task completed. This time the research ran without surprises. Everything went as it should be. Task 4.2A completed. Secondees from DIR and ZAM, with the help of members of the TUK team, performed a series of tests and measurements on the material samples obtained in the previous task.

All planned properties were determined, in particular: Young’s modulus, ultimate tensile stress, breaking stress, strain at ultimate stress, strain at break, impact strength, hardness and linear shrinkage, also DSC and p-v-T studies were carried out.

Poland, Lublin, 31 December 2021

Done. Task 4.2B completed. Secondees from DIR and SEZ, with the help of members of the LUT team, performed a series of tests and measurements on the material samples obtained in the Task 4.1.

All planned properties were determined, in particular: melt flow index MFR and MVR, Heat Deflection Temperature HDT and Vicat Softening Temperature VST, temperature of phase transitions, degree of crystallinity and enthalpy, relationship of the specific volume to temperature and pressure. Unfortunately, due to a broken SEM, we did not do the degree of polymer homogenization and microscope laboratory studies of the material structure. We decided to do this research in April-May 2022. Everyone is looking forward to the next secondments, during which Secondees from DIR and ZAM will go to TUK. We stick to the plan and move forward. The end is already visible.

Poland, Lublin, 1 November 2021

New secondments have started. The project teams from the industrial sector from Dirmata (Lithuania) and SEZ Krompachy (Slovakia) will go to Lublin University of Technology (Poland) and start the implementation of the T4.2A task. Together with the representatives of the LUT team, samples for properties tests will be prepared and the following tests will be carried out: Young’s modulus, ultimate tensile stress, breaking stress, strain at ultimate stress, strain at break, impact strength, hardness, linear shrinkage. The research will be carried out with the use of modern equipment at the Faculty of Mechanical Engineering of the Lublin University of Technology. In their research, they will use the skills acquired during the secondments at the beginning of the project.

Lithuania, Kaunas, 21 September 2021

During the secondment at DIR in September 2021 in Kaunas, a T5.4c workshop was held, where the theoretical and practical aspects of building a business plan, risk analysis as well as a plan of expenses and costs, during the implementation of projects and running a business, were presented. Karolina Głogowska from LUT discussed matters related to writing a business plan, which includes among others setting objectives, defining budgets, engaging partners, and anticipating problems before they happen. Then, Ludmila Dulebova from TUK presented a paper on the analysis of risks that may occur during the project implementation. She presented basic knowledge of risks, risk identification, division of risk, risk analysis process and risk management. On the other hand, matters related to the costs of running a business were discussed by Mr. Aurimas Valecka from DIR. The theoretical analysis was supplemented by practical activities, during which everyone present at the training was to develop a business plan for an innovative undertaking. At the end, Janusz Sikora presented the results of the work carried out during the secondments, which took place at ZAM, and the sending institutions were UMI and TUK from the scientific sector.

Poland, Skawina, 30 July 2021

Lithuania, Kaunas, 25 June 2021

Three research teams from the University of Minho (Portugal), the Technical University of Kosice (Slovakia) and the Lublin University of Technology (Poland) went to Dirmet (Lithuania) to carry out the task T4.1. The extruder is ready and running. The extruder should be connected to the electrical network and the extruder and extrusion process should be tested. First of all, the work will focus on measuring material pressure distribution in plasticization system and extrusion head, temperature distribution in individual functional zones of plasticization system and extrusion head, screw torque, unit energy consumption, extruder and process efficiency, die swell, temperature of the extrudate, polymer output, extrusion speed, power conducted to the extruder, power transferred by the polymer. The presented parameters will be measured for two different rotational speeds of the special screw and three different nanofiller shares.

Poland, Skawina, 1 March 2020

Further secondments are starting, this time in Poland. The host is our industrial partner Zamak Mercator, who will host Secondees from TUK and UMI. As part of the secondments, an automatic extruder control and regulation system will be prepared. The extruder is being built at Dirmeta Company in Lithuania. Theoretical foundations and selection of control system components will be prepared by TUK and ZAM, and UMI will be included in the practical works in April. We keep our fingers crossed to make it happen.

Lithuania, Kaunas, 7 February 2020

T5.2.3 Training session entitled: ”Prototyping and production practice on the basis of the new extruder elements” was held on 7 February 2020 in the conference room of the Dirmeta UAB company in Kaunas, Lithuania. The session had an open character and was addressed to the general public. The event was organized by DIR and LUT and was fully in accordance with GA. The training session consisted of two parts. In the first part, 2 long lectures were delivered which presented different techniques of the extrusion process and different calculation methods of twin screw plasticizing systems. Presentations were given by the guests invited for that reason – EAB member prof. Elżbieta Bociąga and MB member prof. Antonio Gaspar Cunha. The second part concerned the discussion and presentation of innovative measuring tools and systems that significantly simplify and shorten the time necessary to manufacture the given parts and to measure them. This training was conducted by representatives of the UAB Metmatus company, who represent the Hoffmann Group company in Lithuania. Finally, Ms Malgorzata Gierulska conducted a workshop on the Polish language, giving a short theoretical linguistic introduction followed by practical session of “Survival Polish”.

The training session covered selected theoretical and practical aspects of various techniques for injection molding as well as modeling and calculating of twin screw systems. It also concerned discussing innovative measuring tools and systems on the example of the premium brand GARANT tools and the high-quality tool brand HOLEX. The training session was closed by a soft-skill-development workshop entitled “Survival Polish”.

Lithuania, Kaunas, 6 February 2020

The workshop entitled: Realization in metal of extruder vital elements and auxiliary parts – results of WP3, comprised in WP5, especially in T5.1d was held in due time and in accordance with the plan. On February 6, 2020 in Dirmeta company, representatives from various centers reported project achievements realized during the tasks T3.1, T3.3 and T3.4. Łukasz Majewski and Karolina Głogowska presented the results achieved during the implementation of task 3.1A, concerning the manufacuring of the Active Grooved Feed Section (AGFS). They presented step by step the order of the individual machining operations carried out to obtain these parts and discussed all the metalworking machines used. At the end they presented individual parts made of metal.

Doc Ludmila Dulebova from TUK presented the entire process of obtaining all the necessary parts for manufacturing the Rotational Barrel Segment (RBS). She presented the results achieved during the implementation of task 3.1B, concerning the manufacuring of the rotational barrel segment. She step by step presented the order of the individual machining operations carried out to obtain these parts and discussed all the metalworking machines used. Finally, she presented individual parts made of metal. She also presented other parts that TUK made under the project.

Next, a representative of Dirmeta, Mr. Aurimas Valečka presented the entire process of obtaining a Special Screw (SS) and frame. He presented the results achieved during the implementation of task 3.1C, concerning the manufacuring of the special screw (SS). Step by step Mr. Aurimas Valečka presented the order of the individual machining operations performed to obtain a special screw and frame. All the machines and tools which were used in this process were discussed. Finally, he presented a special screw and frame made of metal.

Another topic presented at the workshop were the results of choosing auxiliary elements for the extruder, e.g. the main motor, the motor for rotary segment drive, temperature sensors and plastic pressure in the plasticizing system, heating elements, thermocouples for measuring barrel wall temperature. The selection process was carried out during the implementation of task T3.3. The results were presented by Marcin Buczaj from Lublin University of Technology.

Finally, the project coordinator prof. Janusz Sikora, presented the current status of task T3.4 regarding the assembly of the extruder and pointed out that everything is going according to the plan, the pace of work is good, almost half of the work is already done, and the extruder will be assembled in March.

South Korea, Seoul, 27-30 November 2019

From November 27 to November 30, 2019, another event was held in Seoul (South Korea) related to the promotion of new solutions in various areas of life. The event was the Seoul International Invention Fair 2019, at which members of the NEWEX team from LUT and UMI, i.e. Mirosław Ferdynus, Janusz Sikora and António Gaspar Lopes da Cunha presented a solution of an active grooved zone. The solution entitled “Adjusting mechanism of the plasticizing barrel of the extruder” has been submitted for patent protection at the Polish Patent Office under the number P.425593 and has already obtained legal protection by the decision granting the patent number PL 232600. It is with great pleasure that we inform that the international jury awarded this solution with a bronze medal and it won a special prize. Congratulations.

The 13th International Scientific-Technical Conference “ADVANCES IN PLASTICS TECHNOLOGY” took place at the Goczewski hotel in Chorzów, Poland, from 29 to 31 October 2019. The conference was organized by Research Network Łukasiewicz under the patronage of the Ministry of Science and Higher Education Republic of Poland. During this important conference covering topics such as: Developments in Processing Technologies and Applications, Machines and Equipment and Testing and Measurements, a representative of the Newex project team – prof. Antonio Gaspar Cunha from UMI, presented the paper entitled “Polymer Extruder Modeling – Active Grooved Feed Section, Rotational Barrel Segment and Special Screws”. The paper aroused great interest of listeners and was discussed. Congratulations.

Photo Gallery

Photo Gallery

Poland, Cracow, 8-10 October 2019

On October 8-10, 2019, the 10th International Trade Fair for Composite Materials, Technologies and Products KOMPOZYT-EXPO took place in Krakow. The latest achievements in the field of composites, new distribution channels, valuable business contacts are presented at the fair, experiences and information are exchanged. One of these innovations was the new generation extruder concept developed, presented, distributed and promoted by the team within the NEWEX project. Representatives from ZAM (Bogusław Kiszka, Agata Olszewska) and from LUT (Janusz Sikora) actively participated in the event for 3 days. As part of bilateral face-to-face conversations with visitors, the idea of the NEWEX project and the MSC program was presented.

Lithuania, Kaunas, 30 July 2019

Georgia, Batumi, 17-20 July 2019

The 6th International Symposium on Polymer and Advanced Materials took place at Batumi Shota Rustaveli State University. During this meeting, a member of the NEWEX project, a team representative from LUT, presented the work done under this project. The work was done in cooperation with the Technical University of Kosice and concerned possible solutions of the rotary barrel segment intended for use in the new extruder being built. Over 60 people from various countries were present at the conference. Professor Janusz Sikora presented the work entitled “A new solution of the rotary barrel segment of a single screw extruder” and during many direct talks he presented the idea of MSCA programmes, in particular RISE. Both the work and the project itself was accepted with great interest of conference participants. Initial contacts have been established, which may result in scientific cooperation in the future.

Poland, Nowy Adamów, 30 June – 2 July 2019

In the Czarny Staw Hotel in Nowy Adamów near Aleksandrów Łódzki from June 30 to July 2, 2019, the XXII Professor’s Science Workshops took place. During this most important meeting in Poland of representatives of science and industry, the development of the polymer processing school was presented, the areas of development and ecological polymer processes were shown and presentations of currently conducted research were elivered. During the workshops, members of the Newex project from LUT, Anna Rudawska and Janusz Sikora, presented the outline of the Newex project and its achievements and results so far, and conducted the promotion of the MSCA, in particular the RISE program. The interest in the MSC’s activity was high, new contacts and preliminary research plans for the future were established.

Bulgaria, Varna, 19-22 June 2019

Slovakia, Krompachy, 21 May 2019

In SEZ Krompachy a.s. there was an additional workshop for members of the NEWEX project participating in the secondmet to SEZ Krompachy. The aim of these workshops was to show the participants of the NEWEX project the entire production process of the active grooved section of the new generation extruder. The workshop consisted of two parts. The first part dealt with theoretical issues, material, human and technical resources necessary to make all parts of the active grooved section. This information was collected and presented by Mrs Janka Saksova from SEZ Krompachy. In the second part of the workshop, which took place in the production hall of the Company, the process of producing a selected part of the active grooved section was shown. Presentations were led by Mr Jan Kamenicky. The workshop was completed with a demonstration of the operation of the newly purchased modern injection molding machine by SEZ Krompachy. The extruder is manufactred by Arburg and is called Allrounder 370 S 700-170.

Slovakia, Košice, 20 May 2019

On May 20, 2019, TUK hosted the T5.4b Workshop. The aim of the T5.4b workshop entitled: Idea brokering, IPR issues and EU Research Programmes is to present members of the Newex project from the science and industry sector, as well as anybody wishing to participate, because the workshops are open, issues including support, development and implementation of innovative ideas on the example of transferring the results of research carried out in TUK to social and economic practice. Another aim of the workshop is also to familiarize participants with issues related to Intellectual property: copyrights and industrial property, including such instruments as: patents granted in respect of inventions; protection rights for utility models, registration right for industrial designs, protection right for trademarks, registration right for geographical indications, combating unfair competition as well as the presentation of various research and innovation programs offered by the EU within the Horizon 2020 Framework Programme. The 1 st. presentation was about the Idea Brokering, where Assoc. prof. František Jakab, PhD. from University Science Park, TECHNIKOM discussed about this. Assoc. prof. Radoslav Delina, PhD., TUKE described the rules EU Research Programs, where the presentation dealt with issues in Horizon2020, with attention to issues before the start of the project, during the implementation of the project and after the completion of the project. JUDr. Peter Čižmár informed us about the categories of intellectual property in general, subsequently the emphasis was put on copyright, trademarks, designs, patents and utility models in his presentation.

Presentation and subsequent discussion concerning IPR issues was mainly focused on intellectual property in Horizon 2020, on various kinds of intellectual property and on forms of academia-industry cooperation from the legal perspective.

Switzerland, Geneva, 10-15 April 2019

Slovakia, Košice, 20 March 2019

On March 20, 2019, during the “Open Door Day” and ” Mechanical Engineer – Innovator “, the NEWEX project team members from the Technical University of Košice promoted the NEWEX project, its outputs and solutions. The event was held in the University Library at the Technical University of Košice. This event was attended by a broad scientific as well as lay public, represented mainly by researchers and students from TUKE as well as students and teachers from secondary schools.

Slovakia, Košice, 26 February 2019

On February 26, 2019, in the seminar room of the Faculty of Mechanical Engineering of the Technical University of Košice, 74, Mäsiarska St., Management Board Meeting was held, combined with the Expert Advisory Board Meeting. There were people from Poland, Ukraine, Slovakia, Lithuania and Portugal. The meeting lasted from 9.30 to 12.00. The meeting was held to discuss the current state of the project, its results and dissemination of results including public outreach activities and compliance of the project implementation with the plan. Risks related to the implementation of the project were identified as well as ways to minimize these activities (mitigation measures). The first drawings containing elements of the active grooved zone were presented and the objects that need to be bought and made to construct the entire extruder were generally discussed. A plan of future secondments and methods of financing the construction of an extruder were discussed. The Project Coordinator also presented the current status of the Periodic Report and the Termination Report. Decisions were made, which according to MB and EAB are the most effective for achieving the project’s goals and for its positive completion. The impact of the project on the development of employees participating in the project and on SME was discussed.

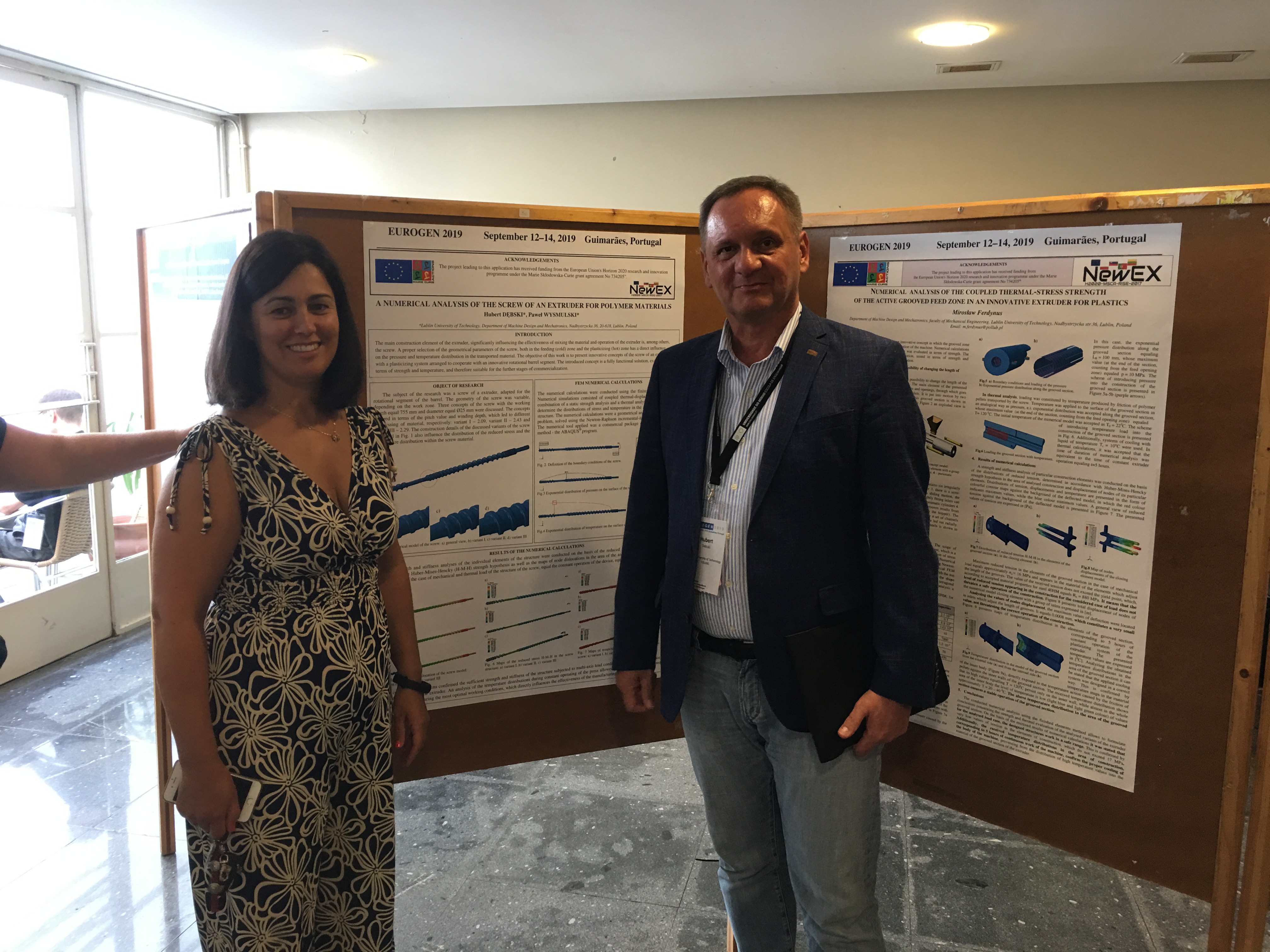

Slovakia, Košice, 25 February 2019

Three weeks after the T5.1c workshop, training T5.2.2 took place, during which the modeling techniques were presented. The meeting was organized by UMI and TUK and it was of an open character. The training was fully in accordance with GA, and its title was: Modelling techniques and practices, experiences of the extruder elements modelling. During the training 4 lectures were presented showing different techniques for calculating and modeling machine parts. Presentations were given by representatives of LUT and DIR. The first lecture entitled “CATIA – multi-module computer system” was presented by Mirosław Ferdynus from LUT, the next one entitled „ABAQUS – computer-aided engineering system” was given by Paweł Wysmulski, the third one entitled „ANSYS – engineering simulation and 3D design software” was delivered by Łukasz Majewski, while the last on entitled „SOLID EDGE – design software for engineers” was given by Edgaras Rimkus. All these presentations showed the capabilities of these softwares and calculation examples.

Slovakia, Košice, 20 February 2019

Additional workshop was held at Kosice, entitled “Generative technologies – 3D printing – case studies – theory and practice”, which was hosted by Ivan Gajdoš from TUK. During the workshop, the participants learned about different printing techniques not only using polymers but also other materials such as metals.

Secondees of the Newex project visited the Department of Biomedical Engineering and Measurement of the Technical University of Košice. The centre offers activities to support innovation of products and technology, optimization of production processes, material efficiency and environmental aspect of industrial applications of technology in the areas of metrology, computer tomography, or in the area of additive biomedical processes as well as industry cooperation.

We could see a device Fortus 450 mc which works on the principle of FDM (Fused Deposition Modelling) and devices: Objet Eden 250 and Objet Eden 260V – working on the principle of POLYJET – the application of liquid material that is cured by UV light used for prototype printing, anatomical models, also used in the dental area, also offers printing from biocompatible material, which can be used in the human body for 24 hours. We also saw Mlab curing R device which works on the principle of SLM (Selective Laser Coating). These devices are ideal machines for manufacturing parts with delicate structures.

This was a very good basis for the T2.6 task consisting in printing the elements of plasticizing systems developed by the NEWEX team.

Portugal, Guimarães, 6 February 2019

On 6th February 2019 in Guimaraes, a workshop T5.1c was organised in accordance with the plan, entitled: Modelling of extruder vital construction elements – results of WP2. LUT and TUK scientists came to UMI to present Secondees from the industrial sector and the remaining members of the NEWEX project the results received in WP 2. In the second part of the workshop lectures and seminars were held to complement the presentations delivered during the workshops conducted under T5.4 on 13-14th November 2018, which concerned the simulation and optimization of plasticizing the polymer in the plasticizing system of the extruder. Therefore Mrs Anna Rudawska from LUT presented the results of task 2.1, Mr Ivan Gajdos from TUK showed the results of the task 2.2. Mrs Karolina Głogowska from LUT and Mr Emil Spisak from TUK acquainted the project members with the results of task 2.3, while the leader of the Portuguese team from UMI showed the results of tasks 2.4. and 2.5. As a result of the analysis and brief discussion, the vital extruder elements that will be made in the prototype were pre-selected. Then, Mr Lino Costa z UMI gave a lecture concerning „Multiobjective optimization”, in which he stated that the engineering problems often have several conflicting objectives. In particular, the optimization of an extrusion process or the design of an extruder is a hard task since it involves several important objectives to be optimized. The goal is to find the Pareto-optimal set, i.e., the optimal operating conditions and the geometrical parameters of extruders that yield the best performance for the manufacturing of a certain product. This optimization problem involves a considerable number of objectives. Multiobjective optimization is a very challenging research endeavor. Advantages, drawbacks and limitations of the classic scalarization methods and evolutionary algorithms were discussed. The problem of handling many objectives and the decision-making process were also addressed. Multi-objective approaches are valuable tools to assist the decision maker to select, from the Pareto optimal set, the more suitable solutions for the screw extrusion process. Then, Mr Antonio Gaspar Cunha presented two lectures entitled “Modelling of the single screw extrusion process” and “Modelling and Optimization: Cases studies”. He showed that the most of the real optimization processes are multi-objective. This is also true when dealing with polymer processing technologies, where it is necessary to determine the operating conditions and/or the system geometry automatically. For that purpose it is necessary to couple modelling routines with optimization routines capable to deal with the multi-objective nature of the problems. In this lesson, multi-objective routines were used to optimize the process of scaling-up in the case of single screw extrusion and on the optimization of the operating conditions and/or screw configuration for the case of co-rotating twin-screw extruders. The results obtained show the validity of the approach proposed. All materials are available in the form of relevant reports and deliverables available from the Project Coordinator, on the Participant Portal website and on the Newex project website, and some of them in the form of quizzes.

Poland, Lublin, 30 January 2019

On 30.01.2019, during the “Innovation Day” held in the Assembly Hall of the Eastern Innovation Center of Architecture of the Faculty of Civil Engineering and Architecture at the Lublin University of Technology, representatives of the world of science presented their achievements to businessmen. The event was attended by scientists from TUK and LUT. Professor Janusz Sikora, prof. Francisek Greskovic, doc. Ludmila Dulebova and dr Jan Varga promoted the NEWEX project, disseminated its effects and solutions developed so far. During the “Innovation Day” representatives of the industrial sector, during cooperative meetings with representatives of the world of science, were encouraged to implement developed solutions, purchase licenses or establish companies with scientists.

Portugal, Guimarães, 12 December 2018

From 7th December to 9th February 2019, more secondments are on the way. This time, industry representatives from SEZ (Slovakia), ZAM (Poland) and DIR (Lithuania) will carry out the project tasks in the Portuguese scientific unit – University of Minho. The purpose of their stay is to carry out research tasks foreseen in the project concerning the selection of the most optimal solution of a plasticizing systems. Team 2.5, consisting of the representatives of three industrial plants as well as members of UMI team will scrutinize the results of modeling, simulation and optimization performed in T2.4 which will enable the selection of the best and optimal technical solution ensuring the lowest possible energy consumption simultaneously with high material productivity and high homogenization level of extrudate as well as other technical parameters. We wish all of them good luck.

Portugal, Guimarães, 20 November 2018

Secondees from SEZ, ZAM and DIR visited PIEP – Innovation Pole in Polymer Engineering. PIEP is a private Research and Development Organization based at the University of Minho, providing consultancy, materials development, product and manufacturing technology development, as well as testing services. With its main core competencies on advanced polymeric systems and composites (thermoset and thermoplastic based), and supported by highly qualified engineering and scientific staff, PIEP is actively engaged in the successful development of innovative products and manufacturing technologies for the industry. The second interesting place was a visit to DONE Lab. DONE Lab, advanced manufacturing of products and tools laboratory, was developed under the partnership between the University of Minho and Bosch Car multimedia through the Innovative Car HMI programme. The IC-HMI program aims to design and develop critical systems and components related to the safety of the car of the future, namely sensors for monitoring the car surroundings, including also driver and passengers, new generation of head-up displays and new concepts of smart assembly tools, among others. For the development of the systems and components, DONE Lab brings together a set of manufacturing technologies capable of assuring the production of experimental and functional prototypes and customized assembly tools, combining additive and subtractive manufacturing technologies. Due to the prohibition of taking photos and disclosing information, the relationship is limited.

Portugal, Guimarães, 13-14 November 2018

On November 13-14, 2018, workshops on cross-sectoral and international cooperation were held to provide a general view on environmental issues related to plastic waste in order to transfer practical knowledge and skills to industrial participants. The workshop was devoted to creating close relationships between the scientific and industrial sectors and building, based on this cooperation, spin-off and spin-out companies in order to commercialize innovative ideas emerging at the university. An approach to scientific and technological problems regarding technology transfer to develop innovative solutions and impact on industry and research was presented. Cooperation between research workers and industry was also discussed, through the presentation of examples, difficulties, discussions and conclusions. The workshops raised the participants’ awareness of the challenges posed by plastics and the environment. The first day of the workshop was devoted more to the University of Minho, presented the history of the university, its scientific, human, organizational and technical potential, the projects that were and are implemented and their effects. The second day of the workshops concerned current issues devoted to the environment protection and sustainable development in the context of polymer waste and concerned the whole process of creating companies benefiting from the university intellectual resources and academic entrepreneurship. The workshops were conducted by Ms Conceição Paiva from the Department of Polymer Engineering and Ms Adriana Cunha from TecMinho. The first leader opened the discussion with the presentation „Plastics and Environment: Threats and Opportunities: A general look over environmental issues associated with plastics waste”, which highlighted different problems associated with plastics waste management, from plastics for long term applications to short lived applications, setting the need for environmental impact assessment based on life cycle analysis. An analysis of the waste management situation in Europe and USA, and some global observations were made. The need for solutions based on design for reuse and recycling was highlighted. Ms Adriana Cunha gave a presentation entitled „University-Industry collaboration: from collaborative projects to spin-offs”, which discussed the conditions for success by spin-off or spin-out companies, which depends on the availability of financial resources, a strong scientific foundation (institutional scientific base), technological and business knowledge resources, focused on a specific application and market niche as well as on business experience. The advantages and disadvantages of spin-off and spin-out companies as well as barriers in their formation were enumerated and discussed.

Portugal, Guimarães, 8 October 2018

From 8th October to 8th December, more secondments are on the way. This time, industry representatives from SEZ (Slovakia), ZAM (Poland) and DIR (Lithuania) will for the first time carry out the project tasks in the Portuguese scientific unit – University of Minho. The purpose of their stay is to carry out research tasks foreseen in the project concerning the design of virtual models of plasticizing systems and the impleme the participation in the inter-sector and international cooperation workshop organized by UMI. The plans include a visit to an innovative enterprise and an institution established for the commercialization of scientific research. We wish them all good luck.

Kaunas, 14 September 2018

On September 14, the Secondees from LUT, UMI and TUK together with colleagues from the Dirmeta company, visited an innovative production plant with 15 years of tradition and an area of 4,000 square meters, with social facilities and modern technical resources. It fulfills small and medium size orders for semi-finished and finished products. The plant is called KMT Jsc, is located near Kaunas and specializes in metal laser cutting, bending, welding, milling, sandblasting, painting and manufacturing of customized metal structures. The state-of-the-art machineries located there are able to process various metals of different sizes and thicknesses. The plant can perform modifications concerning the extension, expansion or elevation of a semi-trailer and can fasten specialist equipment in the form of washing devices, ladders, baskets, etc.

On that day, we also saw the IX Fort Museum in Kaunas. The museum presents the military aspect of the fortifications, but the emphasis is put on the martyrdom of the Lithuanians during World War II. During this visit we got to know the tragic history of Lithuania in 1939-45. It is worth noting that the museum shows not only the German occupation, but also the Soviet occupation, which lasted until 1990.

Georgia, Tbilisi, 9-13 September 2018

On September 9-13, two members of the NEWEX project, Janusz Sikora and Łukasz Majewski, participated in the 26th edition of the international scientific conference PolyChar World Forum on Advanced Materials, which took place in Tbilisi (Georgia). The main thematic scope of the conference included testing properties and processing of polymeric materials. Over 60 participants attended the conference, presenting over 70 scientific papers in the form of lectures or posters. During the conference, the members of the NEWEX project presented the results of the research and project work carried out so far in the form of two posters. The first of them entitled ” Analysis of the present and new solutions of the adjustable grooved feed section of the extruder” discussed previous constructional models of the grooved feeding zone of the extruder as well as the new solution developed in the NEWEX project. The second work entitled “Microscopic evaluation of the halloysite nanotubes dispersion in the polyethylene matrix” described the results of the studies presenting the nanoparticle dispersion in a polymer matrix obtained on a conventional single screw extruder, which will be a comparative point for future investigations of an innovative extruder with active rotational sleeve of the barrel. Both works aroused keen interest among the conference participants, and their authors had to answer numerous questions. Participation in PolyChar 26, in addition to the presentation of research results, was also an opportunity to promote the project among researchers from outside the European Union who came to conferences from such countries as Russia, Japan, Armenia, Georgia or the United States.

Kaunas: 5 September 2018

At the training on September 5, 2018 at the UAB Dirmeta company in Kaunas, Lithuania, prof. Janusz Sikora presented models of screws that were developed after brainstorming on August 6, 2018, discussions and consultations conducted by members of research teams from LUT, TUK, UMI and DIR. Eight models of screws were presented, with different geometrical features, structurally adapted to the previously selected geometry of the rotational barrel segment. Numerical calculations have been started for selected models.

Preliminary results of calculations using the finite element method (FEM) on the cases of screws loaded with the torque, pressure and temperature were presented by Hubert Debski and Paweł Wysmulski from LUT. The assumptions for the calculation of polymer flow in selected screws were briefly presented by Antonio Gaspar Cunha from UMI. After a short discussion and directions for further action, Aurimas Valečka from DIR led the “Survival Lithuanian” course. The aim of the course was to get the Secondees acquainted with a very basic knowledge of Lithuanian that would help them to “survive” in Lithuania. In this intensive course the Secondees learned to introduce themselves, to provide basic biographical information, to ask for the prices while shopping, to ask for directions, basic information at the university, to order food, as well as other useful everyday phrases in Lithuanian. This intensive course was structured around the sociocultural knowledge of Lithuanian language, history, traditions and evolution.

In the second part of the day the Workshop on design and manufacturing of machine parts took place and was led by Povilas Padleckas, the CEO of Dirmeta with the support of the employees from different departments. The workshop was designed to support our knowledge by providing demonstrations of machining, cutting, milling, drilling, turning and other manufacturing processes. The workshop also showed the process of heat treatment of the shaft, sandblasting process for small parts and the process of electro-erosion using an electrode in the form of a moving wire.

Kaunas: 6 August 2018

On August 6 2018 in UAB Dirmeta company (Kaunas, Lithuania), a workshop was held concerning the current constructional solutions of the screws used in the plasticizing systems of such processing machines as the extruders. The workshop was dedicated to members of the NEWEX project and Secondees from UMI, TUK and LUT took part in it. In the beginning, the host of the meeting, Mr Povilas Padleckas, the CEO of Dirmeta presented in an interesting way the history of the company, its development, technical capabilities, human resources and the most important achievements. Edgaras Rimkus and Mindaugas Karnickas from DIR helped him in this. Next, he invited us to visit the plant. During this visit it was possible to get acquainted directly with machines and devices constituting technical resources and manufacturing and machining capabilities of Dirmeta company. Then, Ivan Gajdos, D., Sc., M., Sc., in his presentation entitled ”Screw design – state of the art” showed different screw designs known so far. He talked on the development of the screw design, geometrical features of the screws, their shearing and mixing elements and on using different types of screws for different types of polymers. After the break there was a brainstorming concerning the design of the special screw. First, prof. J. Sikora showed several concepts of newly designed screws, geometrically adapted to the design concept of a rotating barrel segment adopted as a result of the implementation of task T2.2 and he initiated a discussion on that subject. Prof. Antonia Gaspar Cunha, Mr Cezariusz Żmuda, Mr Paweł Wysmulski and prof. Hubert Dębski presented their ideas. As a result of the discussion, design concepts for special screws were indicated in order to be developed, and three of these concepts will be selected for further stages of the project implementation.In the second part of the day, a visit to the Kaunas University of Technology in the Faculty of Mechanical Engineering and Design took place. Secondees from UMI, TUK and LUT familiarized themselves with the areas of the Faculty‘s researchers and scientists interests, which include various topics of mechanical engineering, vehicle engineering, energy and energetics technology and material engineering. The Faculty is also actively involved in various art and design practices.

Lublin: 23 February 2018

On 23 February 2018, the Mid-term meeting of NEWEX project was held in Lublin University of Technology in room 107 of the Faculty of Mechanical Engineering. The meeting lasted from 9.30 to 16.00.

All participants of the project were informed about the meeting in December 2017 and at the beginning of January all leaders received a preliminary agenda of the Mid-term meeting, which was approved by the Project Officer from Research Executive Agency.

All participants of the project were invited to take part in the meeting and additionally the CEO of Dirmeta Company from Lithuania was expected to come. The MTM was attended by 30 people: most members of research teams from all institutions participating in the project with their leaders members of Expert Advisory Board and a special guest from Brussels, Mr Rodrigo Gutierrez Dominguez, a representative of Research Executive Agency.

The Opening Remarks were provided by Janusz W. Sikora. Mr Rodrigo Dominguez in a short speech explained the aim of his visit. The next item was Round the Table Introduction, in which particular research teams, Coordinator of the project and the representative of REA presented themselves shortly. Then, Janusz W. Sikora talked about four issues concerning the project. The first one was the description of the general status of the project, the second one included training, transfer of knowledge & networking, the third one concerned Managament, and the fourth one described Impact of the project.

First, Coordynator of the project presented objectives, work program, milestones, deliverables and implementation of the project and then talked about secondments, training activities, events, e-Learning and cooperation. Within management he discussed financial aspects, communication, re-orientation activities, PR, ethics and IPR, and finished his presentation describing dissemination of results and publications as well as communication activities to reach the general public, including the website, publications, participantion in conferences, submittion of patents and other dissemination activities.

Next, Ludmila Dulebova from Technical University of Technology reported the implementation of WP1. This presentation concerned results achieved within the work on the part of the NEWEX project, namely the Work Plan 1: Initial state research and results (zero-state parameters). In the presentation, the results of all experiments carried out in WP 1 were summarized. In conclusion, it was stated that all tasks required under the plan were conducted, no deviations from the initial work plan.

Antonio Gaspar Cunha presented the implementation of WP2. He started from identification of the main tasks to be accomplished: development of the grooved barrel section, the rotational barrel segment and the special screw; modelling and optimization of the geometries proposed and selection of the best elements.

The modelling of the global plasticating includes now the possibility of computing the behaviour of the grooves in the feed barrel section. The program is being prepared to accommodate the rotational barrel segment and the special screw.

The modelling results concerning the groove conceptions selected were presented. From these results, the Solution Model chosen to be implemented in the prototype machine is the Solution Model 1. This solution is characterized by its versatility concerning changes in both the depth and total width of the grooves and by the good capacity of auto-cleaning. Further work includes the modelling of the rotational barrel segment and the special screw and the optimization of the whole process.

While Krzysztof Trojanowski described the activities connected with e-learning and e-platform. In his presentaton, concerning eLearning platform, he shown the summary of 2017 achievements, the plan for 2018 and the further activities. It comprised:

- Technical information: moodle platform, server, configuration,

- Start-up activities: User’s guide, training course: Simple Mathematics Operations, the presentation on the practical aspects and functionalities, the list of platform users,

- 2017 eCourses (structure, content, quizzes, results, summary):

– Extrusion Process: from theory to applications

– Extrusion Process: specific aspects

- Summary and conclusions of the results (Report: summary of 2017 activities),

- Plan for 2018 and the next years (until the end of the NEWEX project).

All eLearning platform activities were positively accomplished in 2017. Further activities provide more extensive and ambitious plan in comparison to the Annex I of the NEWEX project.

After the coffee break, a few Secondees had their presentations in order to demonstrate their contribution to the WP. The speeches were provided by Lino Costa from the University of Minho, Anna Rudawska from Lublin University of Technology and Peter Chorovsky from SEZ Krompachy a.s.

After the presentations, the selected Secondees had short bilaterally interviews to discuss with the REA representative possible critical issues about their experiences within the RISE network in a more restricted setting.

In the second part of the Mid-term meeting, there was a discussion between seconded staff members and the Project Officer Mr Rodrigo Gutierrez Dominguez, which focused on the experiences within the network in terms of administration, supervision and integration, training and scientific aspects. The Project Officer paid special attention to the same aspects.

Coordinator of the project Janusz Sikora thanked Mr Rodrigo Dominguez for helpful comments and tried to show the activities which will be undertaken in connection with these comments.

At the end of this item of MTM agenda Mr Rodrigo Gutierrez Dominguez stated that generally the project proceeds well but the above mentioned aspects sholud be dealt with quickly.

An the end of the meeting the REA representative concluded the discussion by summarising the output of the Network so far and by providing recommendations for the continuation of the project. Coordinator of the project shortly described the next steps in the project conncerning research as well as trainnig, transfer of knowledge and networking. He stated that the meeting was a success and the activities that have been carried out so far in the project are in accordance with the plan and despite the difficulties caused by the termination of the project by one of the Partners there is a big chance to carry on with the project to the successful end. Coordinator thanked everybody for coming to Lublin and for the participation in the Mid-term meeting.

Lublin: 5 February 2018

We would like to kindly inform that on 23rd February 2018 at Lublin University of Technology, a Mid-term meeting will be held, at which a general progress of the project will be discussed, including the implementation of WP 1 and WP2. The Cordinator’s report will cover the general status of the project, training, transfer of knowledge & networking, management and impact issues. This will also be an opportunity for Secondees to give a presentation on the influence of the project on their development and career. During the MTM we will host most of the participants of the project, Managament Board and Expert Advisory Board,as well as representatives from the Research Executive Agency from Brussels. At the end there will be a meeting between seconded staff members and the Project Officer,as well as feedback and open discussions. The MTM agenda is attached below.

Krakow: 19 December 2017

With the courtesy of researchers from Department of Chemical Engineering and Technology of Cracow University of Technology the research teams from ZAM, UMI and TUK have visited campus and chemical laboratories of this leading Polish university. The Institute of Polymer Technology specializes in new composite and nanocomposite materials synthesis, which are tested in laboratories of spectrometry and thermal analysis. Owned by the Institute laboratory of polymer processing is equipped with many machines of ZAMAK MERCATOR, including: single-screw extruder (ZAMAK EHP-25E), twin-screw extruder (ZAMAK EHP-24D with drive module MP1), cooling bath, pelletizer, fibre-stretching device, injection moulding machine and press.

The guests from the research teams had the opportunity to see modern microscope SEM, infrared spectrometer and AFM atomic force microscope. In thermal analysis laboratory Prof. dr hab. inż. Krzysztof Pielichowski talked about research on TG/DSC simultaneous analyzer and thermomechanical analyzer conducted on polymers with reduced flammability. Whereas, dr. Agnieszka Leszczyńska with great enthusiasm and commitment not only showed the possibilities of Cracow University, but presented the achievements of her team of students.

There were also dinners, visiting Cracow old town and tour to the Auschwitz-Birkenau camp in Auschwitz.

Skawina: 24 November 2017

In the first part of the workshop, was held on 24 November 2017 in the scope of T5.4a, three presentations were given related to the commercial activity of Zamak Mercator Sp. z o.o. In the first presentation, MSc. Agnieszka Niedziela presented the history, areas of operation and general offer of Zamak Mercator Sp. z o.o. In recent years, thanks to modern, specialist equipment, its own design office and research and development department, Zamak Mercator has become one of the leading manufacturers of machines for plastics and rubber processing in Poland. In the field of laboratory equipment for extrusion of polymers and composites, the company is the undisputed leader in Poland and a significant supplier of such devices in Europe. For the industry, Zamak Mercator offers both processing lines for extrusion of plastics as well as other machines related to the broadly defined plastics industry. The devices are innovative, energy-saving, pro-ecological and universal. The control systems developed by Zamak Mercator are friendly, facilitate service and provide the possibility of precise process control of plastic processing. During second presentation, Mr Jakub Fic presented the offer of produced by Zmak Mercator laboratory lines and processing machines dedicated for wide range of plastic materials and composites, by using twin-screw modular extruders (both with parrallel and conical screws) co-rotating and counter-rotating. The laboratory machines have diameters of screw between 2 x 12 mm and 2 x 24 mm. Extruders are characterized by cylinders opening in the horizontal plane enabling the observation of homogenization, high operating parameters (temperature up to 450 oC, high torques and pressure inside the cylinder) and a wide range of processed polymers. Dedicated software enables conducting a wide range of tests, archiving results, remote work and visualization of parameters in the form of graphs and charts. The modularity makes it possible to connect various devices to the drive element, such as twin-screw, conical, single-screw extruders and, for example, crushers. In the third presentation, Mr Jakub Fic presented the scope of production of industrial equipment for plastics and rubber processing. These are both individual devices, such as extruders, eg single-screw extruders with screw diameters from 25 mm to 150 mm, as well as entire lines. Examples of such realizations are specialized lines for the production of filament for 3D printers, fiber optic coating lines, cable coating lines, etc. A specific production are miniature plastic extruders used in the manufacture of products used in medicine (tubes and coated wires for surgery at the heart). After the break, Mr Jakub Fic gave a lecture on the commercial approach and market oriented activities undertaken by companies conducting commercial activities, with particular focus on activities carried out by Zamak Mercator. Mr Jakub Fic spoke about the types of marketing, in particular about: online marketing, mobile marketing, outbound marketing, inbound marketing, event marketing, ATL, BTL, Brand Marketing, analytical marketing, B2B marketing and public relations. Zamak Mercator also offers lines for the production of rubber products such as hoses (including reinforced) and gaskets used especially in the demanding high quality automotive industry. Devices in this segment are characterized by high durability, stable work parameters, simplicity of use and reliability. In the second part of the workshop the operation of a modular twin-screw extruder with a screw diameter of 2 x 24 mm was presented. The extruder consists of a drive module in which an electric motor with a gear is mounted. The engine has a power of 26.4 kW. The drive module includes the entire control with a touch panel, a vacuum pump for degassing, a closed cooling system (eg a charging zone) and torque measurement sensors. A twin-screw extruder with a switchable gearbox can be used with the drive module, enabling the screws to work in a co-rotating or counter-rotating mode. The extruder has a cylinder divided horizontally with the possibility of deflecting both the upper and lower part (it facilitates the removal of screws, their cleaning as well as observation of the homogenization process in individual zones). A twin-screw conical extruder module working with drive module was also presented. Also this device facilitates possibility (by gearbox) to work in co-rotating or counter-rotating mode. The unique feature of this extruding module is employment of bypass that enables to work with small samples of material. During workshops also cross-head was presented, which enables coating of cords and wires, cross-head for coating of tapes, straight head for extruding filament for 3D printing and different types of screws for plastic and rubber processing. During workshops also some of articles manufactured on Zamak Mercator extruders were presented. A unique medical device was presented (extruded on single-screw extruder, screw diameter 12mm) which is used in invasive cardiology (wire coated by plastic material with 70% content of tungsten powder). Also shown were filament for 3D printers (ABS, PLA), gaskets made of porous rubber, fertilizer sticks based on PLA and glycerine and tape with PA12 reinforced with glass fiber.

Warsaw, 16 November 2017

On 16.11.2017 the representatives of Zamak Mercator company, within the activities of NEWEX programme, took part in the meeting organised by the National Contact Point for Research Programmes of the European Union Institute of Fundamental Technological Research, Polish Academy of Sciences in Warsaw. The meeting was organised as part of the informative day concerning getting the funds from UE within Marie Skłodowska-Curie Actions – MSCA and was directed to the institutions operating in research and innovations. The programme of the meeting included presentations concerning different aspects of financing of UE projects for the industry sector and scientific institutions. An example of such a project is NEWEX, which includes industry organisations and universities. Apart from practical aspects of participation presented by Zamak Mercator (ZAM), represented by Mr Bogusław Kiszka and Jakub Fic, also the criteria of evaluation and rules of reporting in MSCA projects were presented. Prof. Barbara Nawrot described aspects of MSCA from the point of view of evaluator. The representative of Euraxess Centre talked about the portal for researchers and institutions, whose aim is to increase the mobility of research staff and to enable foreign researchers to begin work in Poland. Besides a big dose of knowledge, the meeting provided a lot of opportunities to get to know the employees of institutions from different sectors who, similarly to Zamak Marcator, appreciate development and innovations.

Nürnberg, 2-5 November 2017

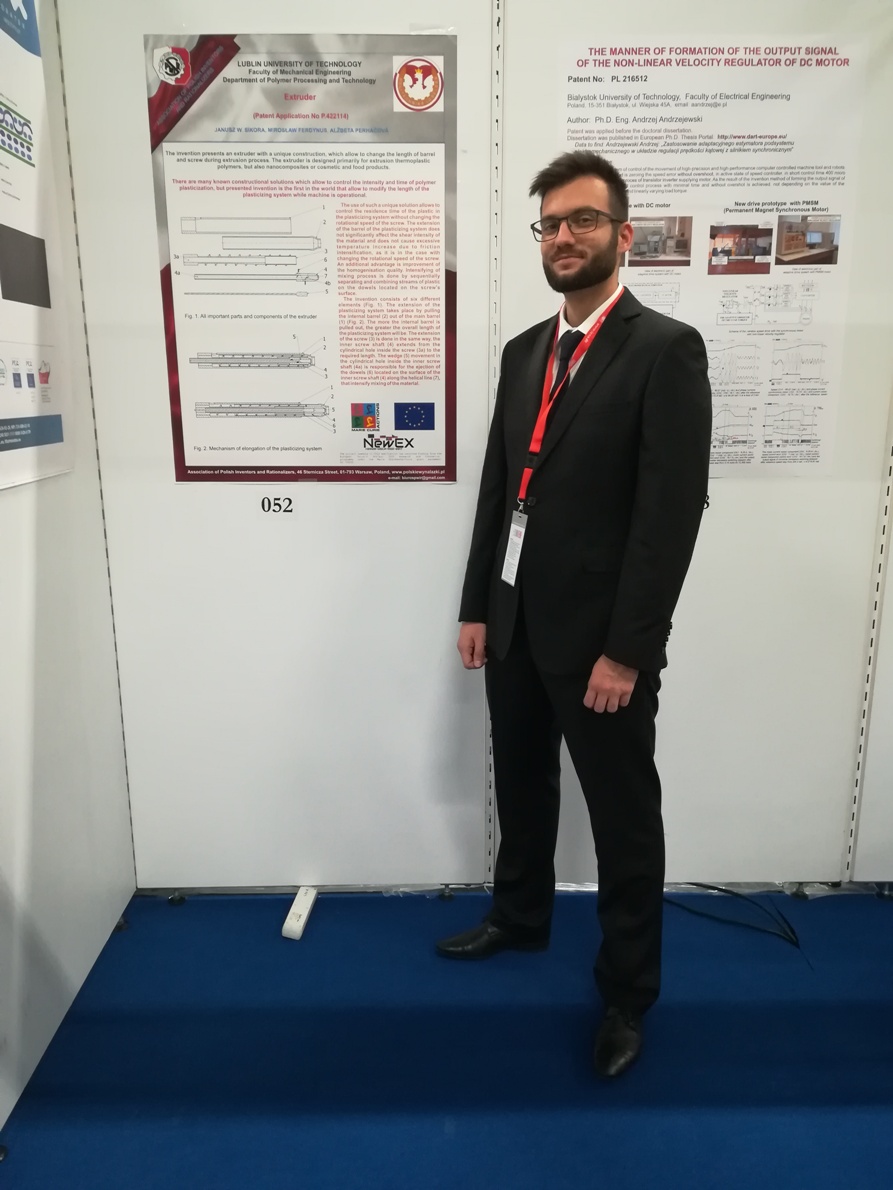

Łukasz Majewski, a member of the Polish team of NEWEX project, was a representative of inventors, who developed within secondments a new constructional solution of the extruder, at iENA 2017 International Trade Fair „Ideas – Inventions – New products”. The invention entitled „Extruder” was submitted to the Polish Patent Office as patent application P. 422114. The invention presents an extruder with a unique construction, which allows to change the length of barrel and screw during the extrusion process. The extruder is designed primarily for extrusion thermoplastic polymers, but also nanocomposites or cosmetic and food products. There are many known constructional solutions which allow to control the intensity and time of polymer plasticization, but the presented invention is the first one in the world that allows to modify the length of the plasticizing system while machine is in operation. International Trade Fair took place in Nürnberg, Germany. International Jury appreciated the invention and awarded it with a gold medal. Congratulations to the inventors!

Skawina: 24 October 2017

In Zamak Mercator LLC, in accordance with WP2, a seminar was held on 24 October 2017 in the scope of T2.2. The seminar was organized by ZAM and had a closed character. The seminar consisted of two parts. Before noon, during the seminar, the members of research teams from UMI, TUK, LUT and ZAM discussed the constructional concepts and technological possibilities of manufacturing the rotating barrel segments of a new extruder. The presentations included describing different concepts of a rotating barrel segment of the extruder. In all solutions, the technical possibilities of using the system of heating the barrel were discussed, as well as transferring the drive onto the rotating segment, ways of assembling, especially sealing, the rotating barrel segment with the stationary elements of the barrel of the extruder plasticizing system. Most of the solutions was presented in the form of virtual 3D models. In the afternoon, the workshops were held concerning twin screw extrusion using a twin screw, parallel, co-rotating extruder with segmental screws of the diameter 2 x 24 mm. The extruded materials were the composite consisting of powdered mineral fertilizer and adhesive in the form of PLA and glycerine as well as polyethylene with MDF flour (Medium-Density Fibreboard) and compatibilizer. The tests were conducted in the temperature 145 oC, at variable screw rotational speed in the range from 10 to 200 rev/min and variable content of the filler from 30 to 60%. During both tests the extrusion process was stopped and the barrel was opened in order to visually estimate the homogenization of the composite in the particular sections.

Skawina: 23 October 2017

Since 23 October the company ZAMAK Mercator LLC (Poland) is the host for members of NEWEX project from Technical University of Kosice (Slovakia) and from University of Minho (Portugal). The scientific aim of their stay in ZAM is to design and make 3D models, make computer simulations of polymer transfer, make strength calculations and optimization of rotational barrel section of a new single-screw extruder. The secondments last for two months. We wish them successful analyses!

Krompachy: 1 September 2017

On 1st September 2017 in Krompachy a meeting was held, during which team members from LUT, UMI and SEZ discussed different models of active grooved section as well as the results of received simulation calculations concerning thermal and strength analysis of this section and the analysis of polymer behaviour during the movement in this section. Dr Mirosław Ferdynus from LUT presented to the participants 8 various complete and functional CAD models, while Dr Hubert Dębski, also from LUT, described to everybody the results of thermal and strength calculations of the presented models. Next, prof. Antonio Gaspar Cunha from the University of Minho presented exemplary results of calculations of polymer pressure and temperature as well as polymer output by the own method developed by UMI employees. After the presentations the participants started a long and versatile discussion concerning the models and the received results in order to accept the directions of optimization of constructional solutions of the developed models to choose the best three for further tests.

Kosice: 27 July 2017

Participants of the NEWEX project from Lublin University of Technology and University of Minho visited on 27th July 2017 the Centre of Research, Development and Implementation of Innovations in Technical University of Košice. The centre offers activities of project-development character to support innovation of products and technology, optimization of production processes, material efficiency and environmental aspect of industrial applications of technology in the areas of CNC machine programming, welding and forming. In the “Centre of Research” project participants saw the work on the lathe type CNC DMG MORI ecoTurn 510 CNC and on the milling machine type DMG MORI / ecoMill 50. Then they explored the whole workplace where laser cutting machine Trumpf TruLaser Cell 3000 CNC is located. They also saw the welding workplace from firm Kemppi type MASTERTIG 2300 and the molding machines, namely the wire cutter type ACCUTEX AU-500i and press type LVD PPEC-6 35/15. The visit in the “Centre of Research” was completed by a car prototype survey, in which students of the Faculty of Engineering also participated. The project participants had a chance to learn about modified hydrogenpowered Jeep and the prototype of lightweight bodywork of a student electric vehicle built on the platform of Volkswagen e-up!. Load off bodywork was solved through modern ultra-light materials with significant mechanical properties based on composites and this car was awarded the Price of International Mechanical Engineering fair trade 2016.The project participants also learned about the construction of an experimental vehicle with the minimum fuel consumption produced for the Shell Eco Marathon races, in which the Faculty of Engineering of the Technical University of Košice participates each year. The Centre of Research, Development and Implementation of Innovations in Technical University of Košice is used for scientific and research activities of basic and applied research, as well as for industry cooperation.

Kosice: 21 July 2017

At Technical University of Kosice, in accordance with WP5, a training was held on 21 July 2017 in the scope of T 5.2.1. The training was organized by LUT and had an open character. The event gathered the representatives of 5 out of 6 institutions taking part in the project. The agenda of this event included the presentation disseminating the idea of RISE with MSCA projects, with special attention to NEWEX project. The first part of the training consisted of the lecture on the results of the studies of the extruder and extrusion process as well as the investigation of extrudate properties, conducted in particular host institutions. The activities concerning training, networking and dissemination were also characterised. In the second part of the training Mr Jakub Fic from ZAM discussed thoroughly the issues concerning practical aspects of filament extrusion for 3D printers on the example of selected plastics. Next, Mr Ján Kamenický from SEZ in an interesting lecture presented the problems of production of metal parts using CNC technology in SEZ Krompachy s.a. Then, the representative of UMI, Mr Antonio Gaspar Cunha described the rules of modelling of screw extrusion and optimization of the screw extrusion processes, pointing out important and essential elements of computer simulation. At the end of this part of training Mrs Anna Sokół-Mazur in extensive presentation Business with passion focused on aspects that nowadays enterprises and projects face with: cooperation, international and intercultural aspects, innovations as the competitive advantage, how to build the effective team in view of personality and age aspects. Then, the constuctional solutions were presented, which were achieved during the brainstorming, discussions and conversations of team members participating in secondments in SEZ Krompachy s.a. which was a host institution. These concepts were further discussed and developed.

Krompachy: 7 July 2017

On 7 July 2017 in SEZ Krompachy company the workshop was held in accordance with T 5.1b, dedicated to NEWEX Project Staff. The agenda of the workshop included the presentation of research results received by particular research teams. The presentations of particular Task Leaders concerned the investigation of the extruder and extrusion process as well as the investigation of extrudate properties. Mrs Karolina Głogowska from Lublin University of Technology discussed the received research results of material pressure distribution in plasticization system and extrusion head, temperature distribution in individual functional zones of plasticization system and extrusion head, screw torque, unit energy consumption, extruder and process efficiency, die swell, temperature of the extrudate, polymer output, extrusion speed, power conducted to the extruder and power transferred by the polymer. Mr Janusz Sikora from Lublin University of Technology presented research results of melt flow index MFR and MVR, Heat Deflection Temperature HDT, Vicat softening temperature VST, temperature of phase transitions, degree of crystallinity, enthalpy, relationship of the specific volume to temperature and pressure and degree of polymer homogenization. Prof. Francisek Greškovič from Technikal University of Košice talked about research results of Young’s modulus, ultimate tensile stress, breaking stress, strain at ultimate stress, strain at break, impact strength, hardness and linear shrinkage. The tests concerned the results received at low and high rotational extruder screw speeds of nanocomposites with PE + PE-graft-MA filled with 2, 4 and 6% halloysite nanotubes. After these presentations the discussion was held concerning the received results and then different constructional designs of active grooved section – the result of Task T 2.1 of WP2 – were considered.

Photo Gallery

Krompachy: 1 July 2017

Since 1 July the company SEZ Krompachy (Slovakia) is the host for members of NEWEX project from Lublin University of Technology. On 4 July members of NEWEX project from University of Minho (Portugal) are joining them. The scientific aim of their stay in SEZ Krompachy is to design and make 3D models, make computer simulations of polymer transfer, make strength calculations and optimization of active grooved feed section of a single-screw extruder. The secondments last for two months. We wish them successful analyses!

Bardejov: 20-23 June 2017

During the international scientific conference Pro-Tech-Ma 2017 and Surface Engineering 2017, which took place at hotel Alexander in Bardejov (Slovakia) from 20.06 to 23.06.2017, the first effects of NEWEX project were discussed. A few scientific papers written during the realization of NEWEX project were presented. Łukasz Majewski and Emil Sasimowski from LUT presented the paper entitled “Unconventional barrel designs of single-screw plasticizing systems”. Mrs Karolina Głogowska from LUT gave a speech on “The effect of adding nano-additives on the properties of thermoplastic polymers” whose co-authors were Jaroslav Hajek from BOR and Stanislav Benčo from SEZ. Janusz W. Sikora from LUT presented the paper entitled “Newex project- research issues and other activities”.

Photo Gallery

Document

Lublin: 9 June 2017

Project teams from SEZ, BOR and LUT visited Lublin Science and Technology Park S.A. on 9 June 2017. The park was founded to facilitate the flow of knowledge and technology between science and business. The mission of LSTP is to support the development of Lublin Province by creating a platform of cooperation between Lublin universities and business and start-up owners. Our teams saw the property and technical infrastructure which is made available for start-up business owners for starting and running own businesses and technology transfer. Lublin Science and Technology Park creates the atmosphere and offers tools for fast development of innovative ideas, offers a variety of free trainings, shares offices and conference rooms, organizes a lot of events and contests for start-up owners. During the visit projects carried out in cooperation with LSTP were presented. One of the effects of this cooperation is a new electric car which was made available for us for testing.

Lublin: 30 May 2017

On 30 May 2017 a study visit took place in the ZOP Co. Ltd FORGING PLANT in Świdnik which specializes in forging processes of aluminium, copper, iron and titanium alloys. The company produces forgings intended to critical parts to W-3 Falcon, SW-4 helicopters, An-28 planes as well as to GTD 350, PZL-10W, TWD-10B and ASz-62-IRm-M18 aircraft engines. Teams from BOR, LUT, and SEZ got acquainted with exemplary production processes of selected aircraft parts of aluminium alloys carried out at this time in the company, starting from designing forgings in the design office by using modern software Solid Edge i NX. Then the visitors got to know the procedures for developing the technology of plastic treatment for the designed forgings of aircraft parts on forging machines (die hammers and screw presses) available in the company. The procedures of preparing thermal treatment of forgings were analyzed. In the next stage the process of designing the technology for mechanical treatment was studied using modern software CAM by Siemens. The study group had the opportunity to observe the technological process of producing ready-made air carrier that is from the stage of shaping the forging from aluminium alloy on the screw press until the next stage connected with the mechanical treatment of the forging into a ready-made part in five-axis treatment centre.

Lublin: 22 May 2017

On May 22, 2017 in Lublin, on the invitation of the Marshal of the Lubelskie Voivodship, Mrs. Anna Rudawska presented the main assumptions of the NEWEX project at the 2nd Young Scientist Forum. The practical aspects of applying for such grants as well as MSC activities have been presented. On May 22, 2017 in Lublin, on the invitation of the Marshal of the Lubelskie Voivodship, Mrs. Anna Rudawska presented the main assumptions of the NEWEX project at the 2nd Young Scientist Forum. The practical aspects of applying for such grants as well as MSC activities have been presented.

Photo Gallery

Invitation

Agenda

Cracow: 15 May 2017

The training which took place in the Centre of Technology Transfer at Cracow University of Technology concerned the possibility of participation of enterprises in European Commission Programme: Horizon 2020. It was organized by the Team of Regional Contact Point of UE Research Projects.The training was held on 15.05.2017 and was attended by Mr Jakub Fic, D.Sc.Eng. from Zamak Mercator, who presented the aspects of participation of Zamak Mercator company in the current project and the rules of carrying out RISE projects.

Lublin: 1 May 2017

On 1 May 2017, Lublin University of Technology hosted the team from BOR, Czech Republic: Ivar Grünbaum and Petra Hájková and the team from SEZ, Slovakia: Filip Ladislav, Ján Kamenický and Janka Saksová. Their secondments started on 01.05.2017 and are due to finish on 30.06.2017. We wish a successful stay!

Kosice: 25 April 2017

On 25.04.2017 within arrival of project participants from firms Borra s.r.o. and Zamak Mercator Sp. z o.o. at TUKE was carried out a workshop on selected techniques for studying properties of composite and nanocomposite

materials and their treatment. Workshop was held at the selected laboratories of Institute of Technologies and Management, Department of Mechanical Technologies and Materials. The laboratory of mechanical and technological testing focuses on the research of mechanical and technological properties of materials. Project participants from SEZ and ZAM got to know the methodology of the research and the essence of devices operation on the example of Tiratest 2300 tensile testing machine and the one for hardness testing. In the Rapid prototyping laboratory was presented the work on a 3D device type FORTUS 400mc for rapid prototyping of Polycarbonate and Ultem prototypes, and on the 3D printer DIMENSION SST 3D Printer for the rapid production of ABS prototypes. The workshop was continued in the laboratory of CNC machine programming, where the project participants got to know and saw the work on the CNC milling machine EMCO concept Mill 155 and CNC lathe DMG CTX 310 eco. The workshop was completed in the plastic processing laboratory, which is aimed at verifying the functionality of molds, pressing and testing of plastic moldings. On the Demag injection molding machine were performed the demonstrations of injection molding process. Within the workshop the project participants explained the principle of working with equipments: TGA /DSC thermogravimetric analyzer, Shore hardness (A, D), Charpy hammer and Raman spectrometer.

Kosice: 13 April 2017

On 13 April prof. E. Spisak from TUK talked about the field of transport phenomena as the basis of modeling in polymer processing. This workshop lecture presented the derivation of the balance equations and combined them with constitutive models to allow modeling of polymer processes. The chapter also presents ways to simplify the complex equations in order to model basic systems such as flow in a tube or Hagen- Poiseulle flow, pressure flow between parallel plates, flow between two rotating concentric cylinders or Couette flow, and many more. These simple systems, or combinations of them, can be used to model actual systems in order to gain insight into the processes, and predict pressures, flow rates, rates of deformation, etc. When solving flow and heat transfer problems in polymer processing, the conservation of mass, forces or momentum and energy must be satisfied. Momentum and energy balances, in combination with material properties through constitutive relations, sometimes result in governing equations that are highly non-linear. This chapter presents the balance equations, making use of constitutive relations presented in this lecture.

Kosice: 13 April 2017

Ing. Ivan Gajdos from TUK, during his presentation on 13.04.2017, talked about CAx solutions for polymer processing technologies. While the extrusion process has been utilized for commercial products since the mid-1800s, designing, modeling and computer simulation is merely in its infancy. However, the advantages offered by CAx technologies make it well suited to further advance the extrusion process through the next decades. Simulation and CAE of the extrusion process and equipment permits a systematic design rather than ad hoc designs based solely on experience. While traditional experimental design of the extrusion process is focused on producing an acceptable product, oftentimes there is no explicit understanding of how process variables interrelate with one another and affect the final extrudate. Simulation also offers significant advantages in the design of extruder screws and mixing devices. Computer simulation allows an engineer the possibility to x201C;try out x201D; numerous new designs on the computer rather than expend time and costs associated with developing and testing a prototype. With the increasing requirements to decrease costs, improve product quality, and increase productivity, CAx solutions provides an important tool to improve quality and throughput and, thus, profitability.

Kosice: 13 April 2017

Prof. František Greškovič from Technical University of Košice during the seminar which was held on 13.04.2017, entitled “Mechanical properties of PA6/MMT polymer nanocomposites and predictions based on the content ofnanofiller” and dedicated to the members of NEWEX project, presented standard methods for material testing. Creating new polymers with desired properties is now more difficult, so there is great place for the modification of known thermoplastics with the addition of fillers. With conventionally used fillers such as talc, calcium carbonate or glass fibers the normal degree of filling is up to 40%. New nanocomposite fillers can improve all kinds of properties with a small degree of filling. This study is aimed at the improvement of basic mechanical properties of well-known polyamide 6 (PA6) thermoplastic with the addition of three different types of nanofillers based on montmorillonite clay. Two fillers Cloisite 30B and Cloisite 93A were organically modified, while filler Cloisite Na+ was in its pure form.

Kosice: 13 April 2017

On 13.04.2017 L’udmila Dulebová from Technical University of Košice during the lecture Characterization of Mechanical and Thermal Properties of Polymer Composites dedicated to the members of NEWEX project presented about possibility of usage of mineral fillers to obtain new properties of polymer composites. She presented effect of mineral fillers Calcium carbonate and talc on main properties of polymer composite with PP matrix. Samples with different percentage of these fillers were prepared and basic mechanical and thermal properties were tested. She informed the members of NEWEX project with research results of testing polymer materials such as thermal conductivity, nucleation of PP and a change in modulus as a result of the change in crystallinity, impact strength, creep resistance, tensile strength, relative elongation and hardness.

Kosice: 13 April 2017